EUROPEAN governments and footwear manufacturers are demanding emergency measures from Brussels to counter the rising tide of shoes and slippers being imported from China.

Figures released by the European Commission yesterday revealed that, after quotas were removed at the end of last year, Chinese exports of six categories of footwear to the EU had increased by almost 700 per cent, and in some instances by more than 1,000 per cent.

Between January and April, Europe imported 162 million pairs of shoes under these specific tariff headings — the equivalent of one pair for every three EU citizens — worth almost €500 million (£335 million). The sudden surge in shoe imports — China exported only 24 million similar pairs during the same period last year — mirrors the dramatic increase in Chinese textile sales to the EU since January after parallel trade restrictions were removed.

Peter Mandelson, the EU Trade Commissioner, is currently trying to persuade China voluntarily to limit its exports of T-shirts and flax yarn. If a deal can be struck within the next few days, he is ready to fly to Beijing to sign an agreement and end the dispute. But if negotiations stall, the Commission will be able to fall back on World Trade Organisation rules and impose its own limits.

Mr Mandelson will undoubtedly use any meeting with the Chinese to voice the latest concerns over the country’s footwear exports. The Commission has been closely monitoring these since January and said in a statement yesterday that it had “noted the concerns of the EU footwear industry”.

A Commission spokesman added: “We have just had these figures. We are looking at them and we are reflecting on what course of action we should take. We will not shy away from acting. To act is to take anti-dumping measures.”

While cheap footwear is a bonus for consumers, it is causing big problems for European shoe manufacturers, especially in Italy, which accounts for almost half the EU’s production, Spain, Portugal and Poland.

Italian manufacturers have sent more than 200 letters of protest to the Commission in the past fortnight complaining that China and, to a lesser extent, Vietnam are dumping leather shoes on the market and putting European companies out of work.

The European Confederation of the Footwear Industry, which represents the Continent’s shoe manufacturers, refused to comment on the latest import figures but is expected formally to request EU action next week.

Several EU governments, including Portugal and Poland, are expected to support action against Chinese exports.

Guangzhou's "shoe street" redoubles production and profits

Haoban Street

People in the shoe, bag and suitcase industry can find everything they need in Haoban Street and its surrounding areas. Haoban Street, Guangzhou, has a history going back 800 years - and it's still going strong, if not stronger, today than ever before.

The huge demand for shoe materials following the emergence of shoe, leather goods and handbag factories in the Pearl River Delta during the 1980s, fuelled the growth of a market for leather, hardware and shoe materials. So a specialized area developed from the already-established Haoban Street to Xiaoxin Street, Yudaihao and Daxin Road. Annual turnover has been ratcheted up to hundreds of millions of yuan.

The nature of the area's success is hardly surprising, because shops here supply materials to China's top 10 shoemakers, including Great Wall and Senda. Experts note that Haoban Street not only leads market trends in South China but is also the barometer for the entire national market's demand for shoes and materials.

The variety of merchandise sold in Haoban Street is becoming increasingly varied. As well as traditional cowhide, artificial leather and regenerated leather are also on offer. Accessories for leather goods, such as buckles, shoe decorations, shoe studs and decorative plates in gold, silver and bronze can all be found here. There are about 700 kinds of bonding agents, hide cutters, threads and other materials. The lasts sold here are exquisitely made and come in all styles and specifications.

materials for shoe uppers

Haoban Street's boom has attracted businessmen from Zhejiang, Fujian, Sichuan and other parts of Guangdong, while nurturing a new generation of "shoe tycoons". Ye Zhicheng, the "kingpin" of Haoban Street, came from a family that has been dealing in shoe materials for generations. His family now owns more than a dozen shoe shops, and five of these are under his own name.

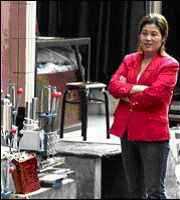

Miss Liang, the "queen" of Haoban Street, has been assisting her father in his shoe materials business since the 1980s. She began by distributing soles and materials from Hong Kong. In fact she eventually helped to create a local market for ready-made soles in Haoban Street, and she is also the first to market foreign bonding agents here. Today, she has four stores on the street.

Liang Fugen is the newly-elected vice president of the Haoban Street Leather, Hardware and Shoe Materials Industries Association. His Yongfa Leather Shoe Materials Co grosses about US$10 million a year in business with Hong Kong.

On the other hand, most of the players in Haoban Street are small operations with workshops at the back of the outlet. There are also those that started off as small workshops but eventually expanded into big business and even large modern companies.

Li Guoqiang is a long-term resident in Haoban Street. He operated a shoe workshop in the early 1980s, at first carrying out everything by hand. Later he spent more than Rmb10,000 (HK$943.3) and bought his first shoe-making machine. As business grew bigger, he set up Guoqiang Shoe Factory. Now his Xinlong Holdings Company has its own leather shop as well as shoe last and shoemaking factories.

By 1995, there had been over 800 shops in Haoban Street and its neighbouring area. The Haoban Street Leather, Hardware and Shoe Materials Festival, which was first held in 1999, now attracts thousands of businessmen from other parts of the Chinese mainland, as well as from Hong Kong and Macau each year.

Following WTO accession, the shoe materials market in China is expected to become more vibrant and competitive. Although Haoban Street is famous nationwide, the place has for years lacked planning because of its inner city location.

As a result of its haphazard development, the market finds itself in a defensive position compared with newer rivals. With this in mind, the government joined hands with the local business community and began improvement works in two stages during June 2001.

What I do is kick them in the pants with a diamond buckled shoe!

~~Aileen Mehle~~